Designed for fragile bulk materials, the TH Series uses an internal cascade cone system to limit material velocity. It minimizes product breakage and impact dust, making it ideal for grain, fertilizer, and coal stockpiling.

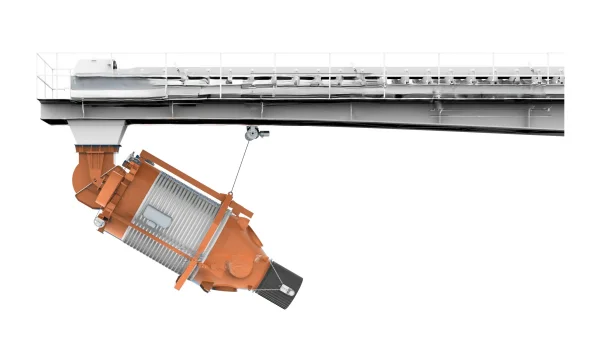

TH Series Cascade Chute

- Product Introduce

- Advantages

- Application & Gallery

Introduction

Our cascade chute is a bulk material transfer and loading device designed to control material flow velocity, reduce dust emission, and minimize wear and product degradation during gravity-fed material handling. This telescopic cascade loading chute uses a series of inclined internal cascade plates or spiral flow channels to guide material downward in a controlled manner instead of allowing free fall.

- Flow rates of 200-5000 t/h are attainable with most materials.

- Extended lengths to 100 feet and more if needed.

- The cascade chute system can reduce dust emission levels to as low as 5mg/m3.

Working Principle

Bulk material enters the cascade chute from the conveyor discharge and flows along step-by-step cascade surfaces:

- Each cascade step reduces the vertical drop

- Impact energy is absorbed progressively

- A continuous material stream is maintained

This design significantly reduces dust generation, spillage, and wear compared with conventional straight drop chutes. By using this technology, dust generation is practically eliminated at source, without the need for expensive, energy-intensive and high maintenance, dust extraction and filtration systems.

Advantages & Highlights

-

Lower Maintenance and Operating Costs

Lower impact forces on chute structure and receiving equipment to reduce chute and conveyor wear.

-

Effective Dust Suppression Without Complex Dust Collectors

Controlled gravity flow without free fall to reduce material velocity and impact to reduce dust.

-

Reduced Material Segregation and Degradation

Without free fall loading, it can reduce the dropping height to reduce material breakage.

-

Lower Noise and Vibration Levels

Lower impact forces result in less equipment vibration and less noise, providing a quieter working environment.

Application & Gallerys

Telescopic cascade chutes are commonly used at places where environmental protection and material quality are important.

- Conveyor transfer points

- Truck and rail wagon loading

- Ship and barge loading

Our cascade loading chutes are commonly used in handling bulk materials like these:

- Cement and clinker loading

- Coal and coke handling

- Fertilizer and chemical bulk loading

- Grain and food-grade materials

- Iron ore, sand, and aggregates

- More Fragile materials.

Contact Us for Quotes and Prices!

Just let we know what you want, and we will get in touch with you as soon as possible!

English

English