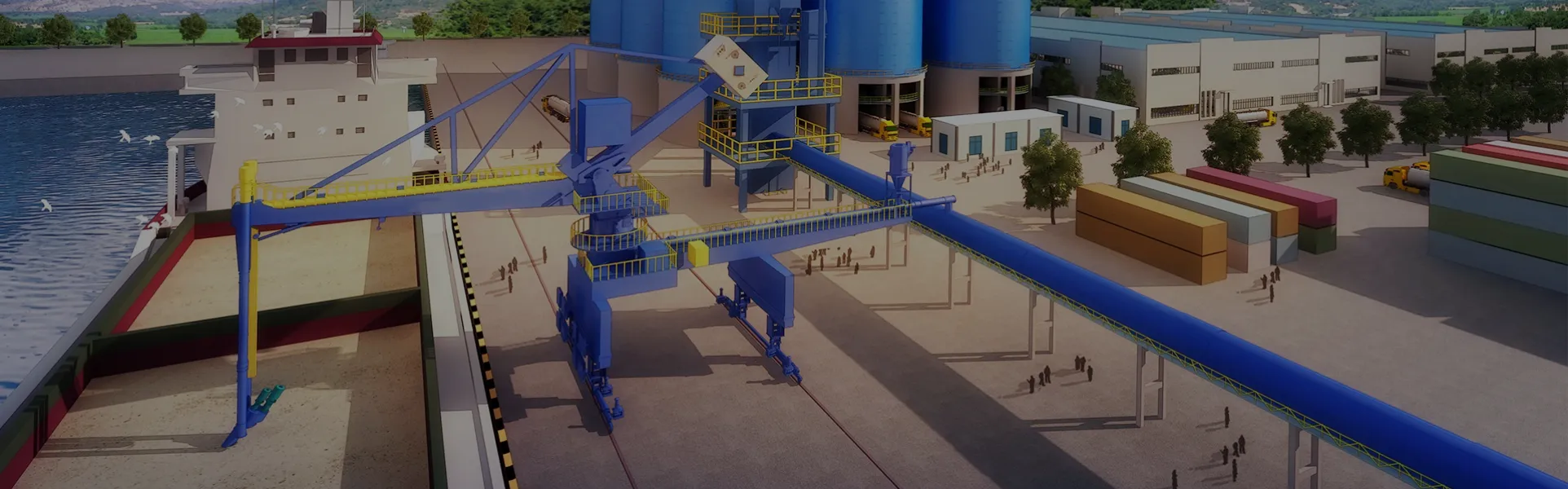

A ship unloader is a type of bulk material handling equipment used to unload bulk materials from ships. Our ship unloaders are essential in ports and terminals for efficient and quick unloading of cargo. Ship unloaders are crucial for efficient and rapid unloading of bulk materials in various industries. Their design, capacity, and features can be tailored to specific operational needs, ensuring optimized performance and cost-effectiveness.

Discover our Ship Unloader

By Machine Category

Bulk Material Ship Unloader

-

Chain Bucket Ship Unloader

View More Send A RequestThe chain bucket ship unloader utilizes a series of buckets attached to a continuous chain or belt to scoop and lift the material from the ship's hold, transporting it to a conveyor system or directly to storage. The unloading capacity can reach 3000t/h.

-

Screw Ship Unloader

View More Send A RequestScrew ship unloaders are essential for the efficient and continuous unloading of dry bulk materials with screw conveyors. The unloading capacity can reach 1500t/h and it is suitable for ships ranging from 500DWT to 70000DWT.

-

Grab Ship Unloader

View More Send A RequestA grab ship unloader uses clamshell bucket to scoop materials from a ship's hold. The unloading capacity can reach 2500t/h. The unloading bulk material lump size can reach 300mm.

Video

What Are The Applications of Ship Unloaders?

Ship unloaders are essential pieces of equipment in the logistics chain for handling bulk materials. Their ability to handle different types of materials and their high efficiency make them indispensable in modern bulk material handling operations. Whether in ports, power plants, steel mills, or other industrial applications, ship unloaders play a vital role in ensuring the smooth and cost-effective unloading of bulk cargo.

- Ports and Terminals: Unloading bulk cargo such as coal, iron ore, grains, fertilizers, cement, and more.

- Grain: Handling bulk grains like soybeans, corn, wheat, soybeans, etc.

- Wood: Handling bulk wood products like saw dust and wood chips.

- Power: Handling bulk fuels like coal delivered by ship.

- Steel: Unloading raw materials like iron ore, coal, coke, etc.

- Cement: Handling bulk cement, clinker and other raw materials.

- Others

Specifications of Bulk Material Ship Unloaders

| Feature | Grab Unloader | Chain Bucket | Screw Unloader |

| Max Capacity (TPH) | 3,000+ | 6,000+ | 2,000+ |

| Material Size | Lumps (up to 1m) | <300 mm | <50 mm |

| Dust Emission | Moderate | Low | Very Low |

| Energy Use | Medium | High | Medium |

| Automation | High | High | Medium |

| Maintenance | Moderate | High | Moderate |

| Customization | Yes | Yes | Yes |

| Material Suitability | Coal, iron ore, grain, aggregates and more. | Coal, grain, cement, fertilizers and more. | Grain, cement, fly ash, fertilizers and more. |

Why to Invest Our Ship Unloaders?

-

HHigh Efficiency

Capable of unloading large quantities of material quickly, reducing ship turnaround times.

-

Versatility

Our ship unloader is suitable for a wide range of bulk materials and different types of ships.

-

Durability

Built to withstand harsh marine environments and the abrasive nature of bulk materials.

-

Safety

Our ship unloaders are equipped with safety features to protect operators and reduce the risk of accidents.

-

Environmental Control

Options for dust control and environmentally friendly operations.

Contact Us for Quotes and Prices!

Just let we know what you want, and we will get in touch with you as soon as possible!

English

English