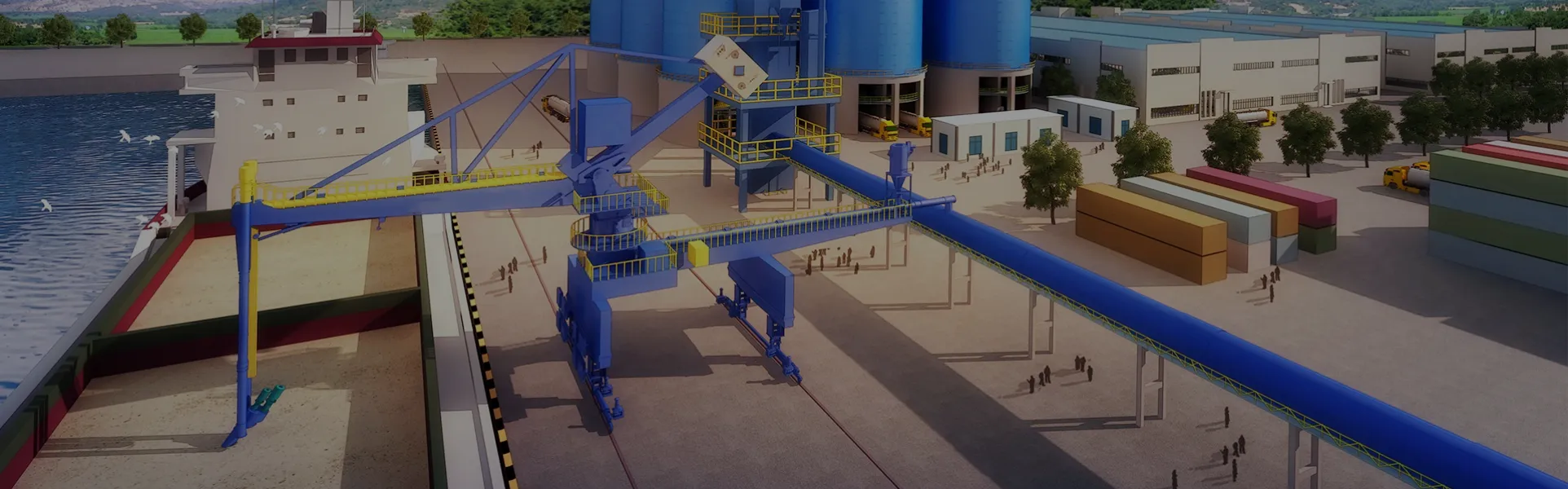

This type of unloader is especially effective for handling dry bulk materials such as grains, cement, alumina, and other similar commodities. The screw conveyor mechanism provides a continuous and controlled flow of material, making it suitable for various industrial applications.

Components of Screw Ship Unloader

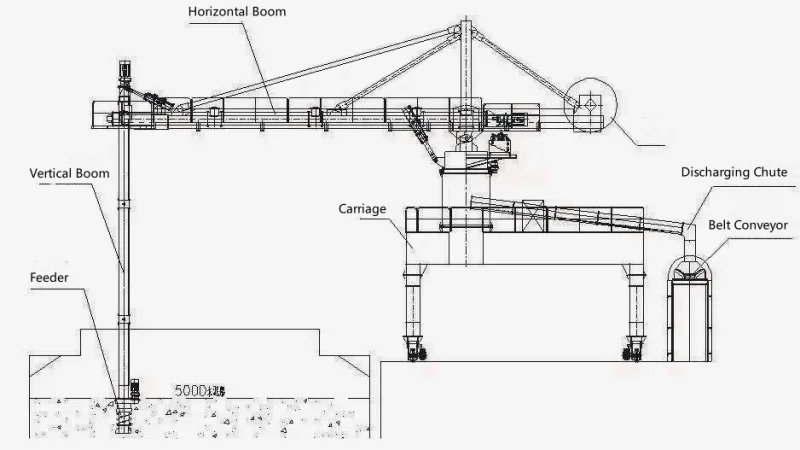

- Screw Conveyor: A helical screw element housed in a tubular or trough casing that moves material along its length. The screw conveyor can be either horizontal or inclined.

- Inlet Feeder: A mechanism that directs the material from the ship’s hold into the screw conveyor.

- Discharge System: Transfers the material from the screw conveyor to the next stage, such as a conveyor belt, hopper, or directly into storage.

- Support Structure: The framework that supports the screw conveyor and associated components. This structure must be robust to handle the weight and movement of the equipment and materials.

- Drive System: Powers the screw conveyor, typically consisting of motors, gearboxes, and drive shafts.

- Control System: An operator control cabin or panel where the unloader’s operations are monitored and controlled.

Screw Ship Unloader Drawing

Operation of Screw Ship Unloader

- Positioning: The unloader is positioned over the ship’s hold.

- Feeding: The inlet feeder directs material from the hold into the screw conveyor.

- Conveying: The screw conveyor moves the material along its length to the discharge point.

- Discharging: Material is discharged from the screw conveyor to a conveyor belt, hopper, or directly to storage.

English

English