| Model | TRS1020 | TRS1024 | TRS1024L | TRS1031L | TRS1231L |

| Length (m) | 20 (65.61ft) | 24 (78.74ft) | 24 (78.74ft) | 31 (101.70ft) | 31 (101.70ft) |

| Belt Width (mm) | 1050 (41.33inch) | 1050 (41.33inch) | 1050 (41.33inch) | 1050 (41.33inch) | 1200 (47.24inch) |

| Discharging Height (m) | 8.8 (28.87ft) | 10 (32.80ft) | 10.8 (35.43ft) | 12.7 (41.66ft) | 12.7 (41.66ft) |

| Stockpile Volume (m³) | 7141(9340yd3) | 9060 (11850yd3) | 8435 (11032yd3) | 19050 (24916yd3) | 19050 (24916yd3) |

| Stockpile Volume (t) | 11426 | 14496 | 13490 | 30470 | 30470 |

| Capacity (t/h) | 500 | 500 | 1500 | 1500 | 1500 |

| Material density | 1.6t/m³ | ||||

| Note: L stands for lattice steel structure. The L in TRS1024L means that the conveyor body adopts lattice steel structure. | |||||

TRS Tracked Radial Stacker Conveyor

- Product Introduce

- Advantages

- Application & Gallery

- Technical Parameters

Introduction

The TRS Series Tracked Radial Stacker is the ultimate stockpiling partner for mobile crushing and screening operations. By combining a heavy-duty crawler undercarriage with radial movement, this conveyor offers unmatched site mobility and high-volume stockpiling capacity. It allows operators to create massive radial piles without relocating the primary equipment, significantly increasing operational efficiency in quarries and mines. We offer 500t/h and 1500t/h TRS Tracked Radial Stacker with different conveyor lengths. Available in a wide variety of sizes and options to best fit your operation, a conveyor system can simplify your grinding operation, create efficiencies, and increase productivity.

Components of Tracked Radial Stacker

1. Feeding Boot

This steel feed hopper has large receiving area at loading points. The feeding height is adjustable due to the telescopic rear section at the end of chassis. It consists of the following two parts.

- Steel hopper

- Anti-spill skirt

- Wear liner available

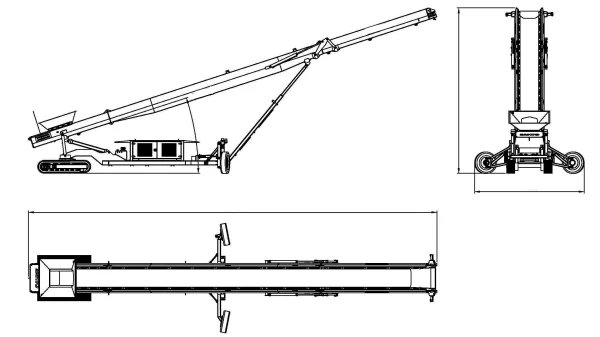

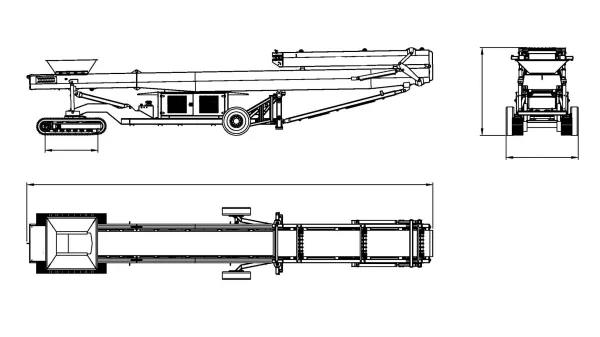

2. Foldable Conveyor

Lattice steel frame and plate steel frame

Heavy duty folded mild steel plate design gives an optimum strength to weight ratio. It use hydraulic system to fold belt conveyor and raise conveyor. It has two types of conveyor frames.

- Plate steel frame (0-500t/h)

- Lattice steel frame (600-1500t/h)

3. Tracked Mobile Chassis

Heavy-duty structural steel chassis with integrated fifth wheel pins in the rear and hydraulic jack legs in the front. Features heavy-duty box frame construction for mounting radial arms at the front of the chassis.

- Drive: integral hydraulic motor.

- Tensioning: hydraulic adjuster, grease tension.

- Materials: heavy duty structure.

4. Hydraulic System

Steel fabricated hydraulic tank complete with fill level gauge and lockable filler cap. All conveyor functions by hydraulic lever.

- Raise / Lower Head and tail,

- Start / stop belt,

- head fold / unfold.

5. Engine & Control

It is equipped with engine monitoring and system including tracking and start/stop conveyors. Panel mounted in secure canopy with lockable doors. Steel fabricated fuel tank complete with fill level gauge and lockable filler cap.

6. Radial Arm

Heavy duty structural steel foldable radial arms for in line and radial travel. It is mounted on tyres which will be driven by hydraulic power.

- Internal hydraulic wheel drive in one side.

- Radial movement by hydraulic lever.

- Tyre wheels.

Stockpile Piling Degree

Tracked Radial Stockpile Piling Degree (About 0°, 45°, 90°, 120°, and 150°)

Tracked Radial Stacker Transportation

Tracked Radial Stacker Transportation (1xtrailer or 1x40ft container)

Advantages & Highlights

-

Crawler Mobility for Rugged Terrains

The TRS series is mounted on a heavy-duty tracked chassis, ensuring stable movement on uneven or soft ground. This crawler-mounted stacker can be easily redeployed alongside mobile crushers, reducing the need for wheel loaders and lowering fuel consumption.

-

Automated Radial Stockpiling

With its integrated radial function, the TRS conveyor can rotate to create large-capacity stockpiles. This prevents material segregation and optimizes the use of available space in your stockyard or quarry.

-

Eliminate Double Handling

Eliminate double handling of bulk materials with wheel loaders.

-

High Quality Stockpiling

Automatic radial stockpiling program (Option) reduces degradation, compaction and contamination.

-

Large Stockpile Volume

Radial Stockpile can reach 30,470 tonnes (19,050m3). The horizontal stacking range is 180°.

-

Easy for Global Transportation

Easily shipped on low loader or packed in 1 x 40ft container.

-

Large Lump Size

The lump material size can be up to 300 mm and can be used to connect the primary jaw crusher.

Application & Gallerys

The range of MNSTACKER stackers ensures all applications are catered for from heavy duty primary jaw crushing applications to light duty screening applications. You can use it to handle bulk materials like these.

- Aggregate

- Woodchips

- Sand

- Crushed Rocks

- Mineral Ore

- Others

Technical Parameters

Contact Us for Quotes and Prices!

Just let we know what you want, and we will get in touch with you as soon as possible!

English

English