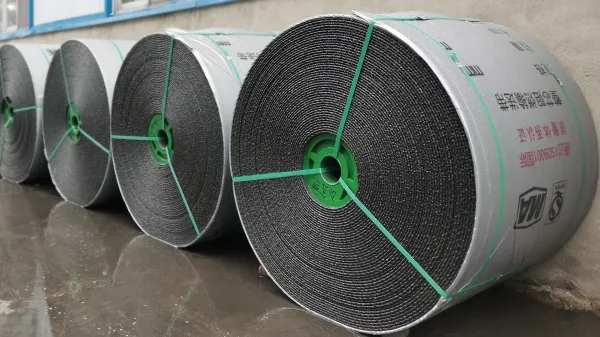

PVC and PVG solid woven conveyor belts are robust, versatile, and designed to handle the demanding conditions of mining and industrial applications.

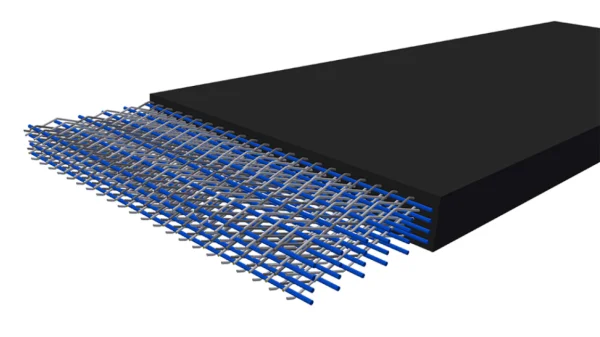

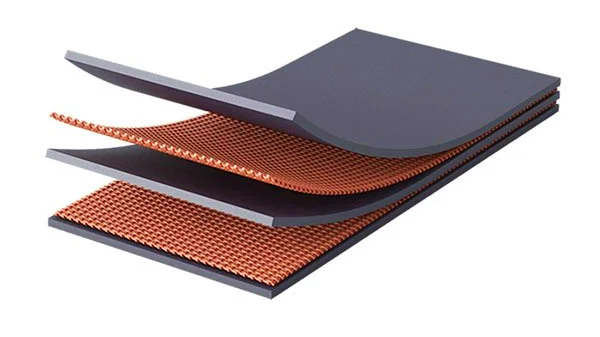

Construction of PVC and PVG Belts

1. Core

Both PVC and PVG belts have a solid woven fabric core that provides tensile strength and flexibility.

2. Coating

- PVC Belts: Coated with PVC on both sides.

- PVG Belts: Coated with PVG on both sides and additionally covered with a layer of nitrile butadiene rubber (NBR).

PVC and PVG Solid Woven Belt

- PVC Type conveyor belt's top and bottom layers are PVC coating cover, Single-sided tape thickness ≥1.0mm, inclined angel:<16°. Solid woven PVC conveyor belts are very suitable for use in coal mines, power stations, chemical and metallurgical industries and other conditions that require fire resistance and antistatic properties.

- PVG Type conveyor belt's upper and lower layers are nitrile rubber and PVC, which have the feature of TPE, single-sided tape thickness: 1mm-3mm, inclined angel:<20°. PVG Solid woven conveyor belts are used to transport oily products, grains, feed, fertilizers and agricultural products.

English

English