Corrugated sidewall belts are a versatile and efficient solution for complex material handling needs, especially where space constraints and steep inclines are a challenge.

Construction of Corrugated Sidewall Belts

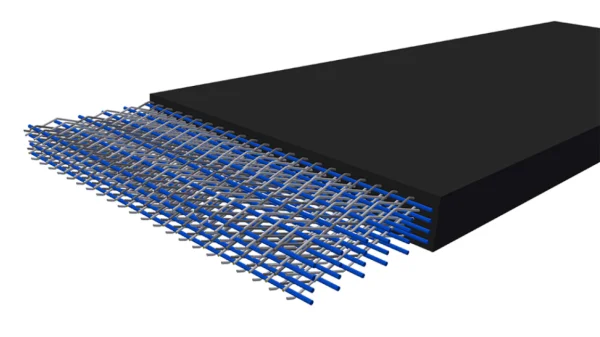

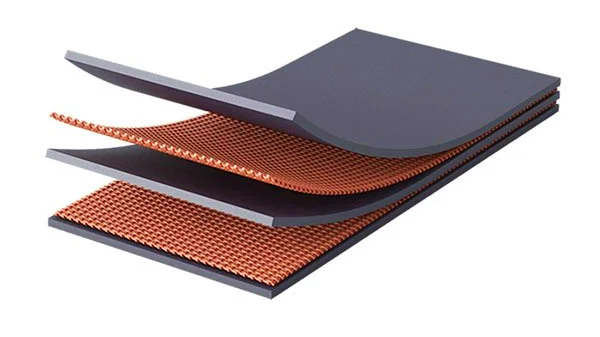

1. Base Belt

Corrugated Sidewall Belt Base Belt

The main body of the conveyor belt, usually made from durable materials like rubber, provides the necessary strength and flexibility.

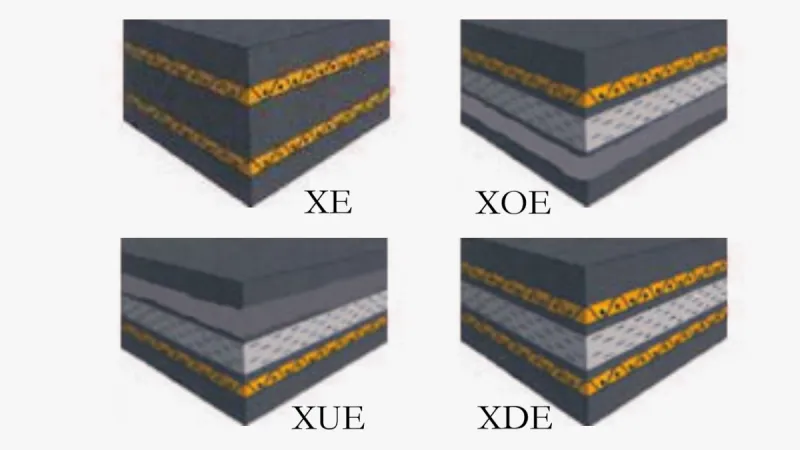

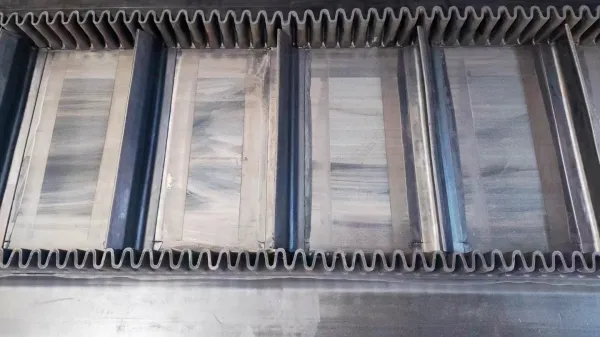

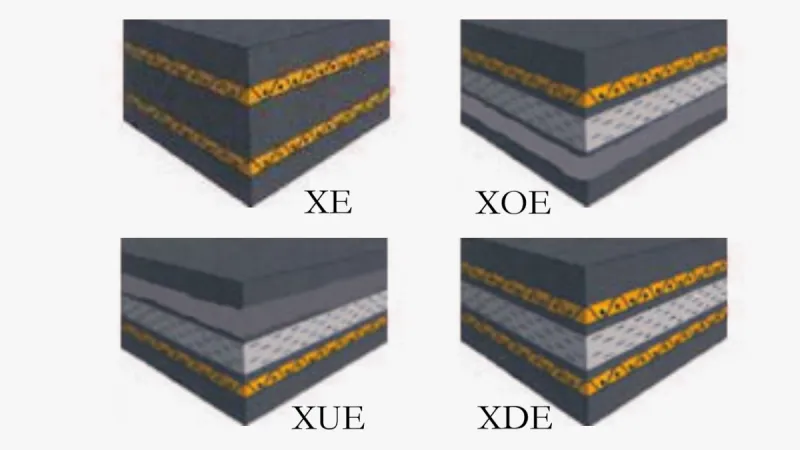

2. Corrugated Sidewalls

BG (Normal Corrugated Sidewall) and BGT (Rubber with Fabric Reinforcement)

These are flexible, vertically corrugated rubber walls attached to both sides of the base belt. They contain the material and prevent spillage, allowing for steep angle conveying.

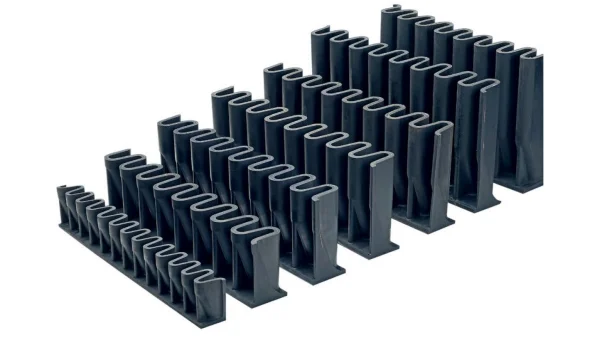

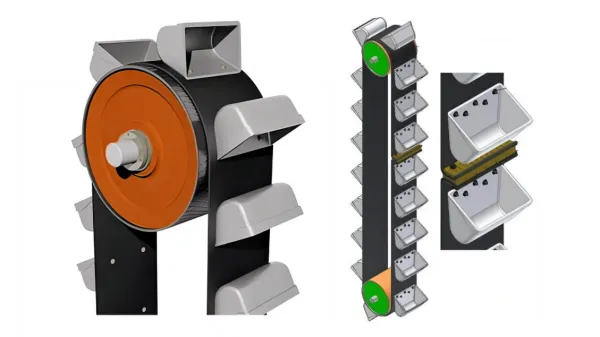

3. Cross Cleats

Cleats of Sidewall Belt

Positioned at regular intervals across the width of the belt, the cleats help hold and transport the material upwards. Cleats come in various shapes and sizes, depending on the material and the incline angle.

Types of Corrugated Sidewall Belts

- Standard Sidewall Belts: Designed for general material handling applications with moderate inclines.

- High-Incline Sidewall Belts: Equipped with higher sidewalls and more robust cleats for transporting materials at very steep angles or vertical lifts.

- Specialty Sidewall Belts: Customized for specific needs, such as oil-resistant, heat-resistant, or flame-retardant belts.

English

English