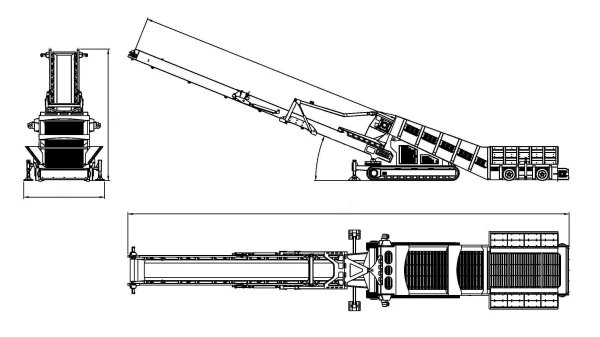

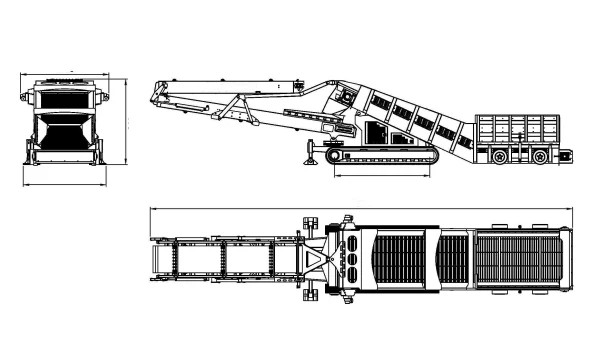

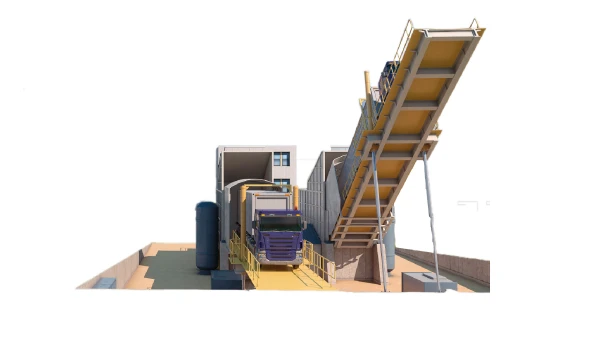

This tracked bulk reception feeder can receive bulk materials direct from dumper trucks. A heavy-duty plate chain belt feeder is used to accept material from the truck, which ensures that large amounts of material discharged from the truck can be transferred in an adjustable and controlled manner. Chain and sprocket driven belts ensure the conveyor of surface feeder does not stall compared to conventional belt feeders. Our truck unloaders mainly consist of the following components.

1. Heavy Duty Hopper

This heavy duty steel hopper has a inclined apron chain belt feeder. It can bear the surge impact of materials discharging from dumper trucks. It mainly consists of the following parts.

- Heavy duty apron chain belt feeder.

- Wear liners.

- Flexible side seal skirting to preven material spilage.

- Adjustable plough to control throughput

- Material broker to reduce impact.

- Dust removal device is available.

truck unloader hopper feeder

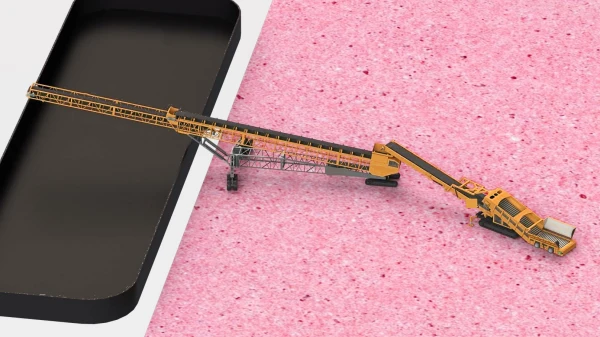

2. Inclide Slewing Conveyor

The conveyor frame design is a critical factor to ensure that the machine is suitable for the task in hand. We provide two types frame to meet conveying applictions. There are:

- Folded Steel Plate Frame,

- Lattice Steel Frame.

- Conveyor cover structure is available.

The feedboot has mild steel liners to protect against abrasive material. And the radial conveyor has more tha 120° of radial coverage.

truck unloader slewing conveyor

3. Chassis and Tracks

The chassis and bottom tracks will move the machine in site and carrying the weigth of the unit.

- Hydraulic jacking legs to improve stability, when inclined conveyor is rotating.

- Heavy duty folded plate design sides.

- lockable access doors to allow easy access to components

- Heavy duty tracks for carrying the unti and moving.

4. Hydraulic System

The hydraulic system is mainly used to realize some actions like folding ,raising, rotating, etc. It consiss of these following components.

- Large steel fabricated hydraulic tank with fill level gauge and lockable filler cap.

- Oil cooler.

- Pumps.

- Others like filters, valves etc.

chassis and tracks for truck unloader

5. Engine and Control

This truck unloader is working as bulk reception feeder, and it integrate engine in its chassis. The engine will compy with high strict global standar and has engine monitoring and tracking system, LED indicator, and panel in secure canopy with lockable doors. The stand-alone Electrical control panel is a control panel that integrates with clients other plant or just the control philosophy so that the client can make their own control arrangements. It has:

- Chute and entry material level probes.

- Rotation sensors and loss of rotation alarms.

- Emergency stops and pull-wires.

- Operational and Maintenance Lighting.

- Start-up Sirens and Alarms.

- Local operator start panel.

- Traffic lights to indicate to operators when to tip or when not to.

English

English