Ability to handle complete range of materials such as; Coal, Grains, fertilisers, Biomass, Ore's (iron, copper, gold, bauxite), Aggregates, Woodchips, Mulch, Wood Pellets, Sulphur, Cement Clinker and many more.

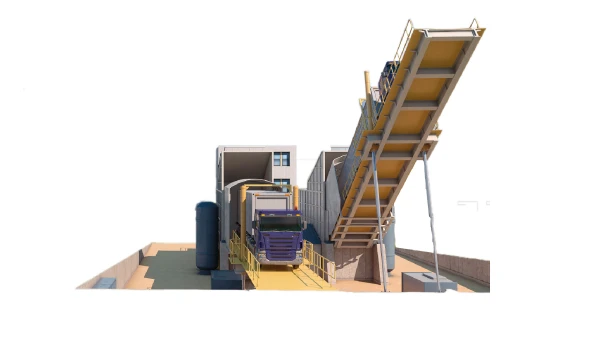

- Drive over Truck Unloading

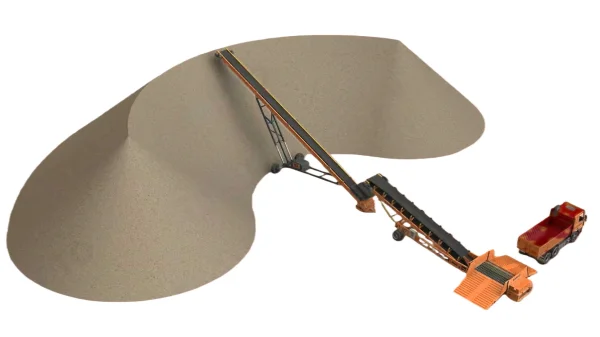

- Mobile reclaim hopper feeding overland conveyor / stacker.

- Rail wagon loading.

- Feeding other conveyors to stack or barge / ship load material

- Directly from wheel loaders, grabs and excavators

- Direct loading from tipping road trucks, walking floor trailers etc.

- Used in Port stockyards, primarily to feed ship-loading equipment

- Can be used to load small vessels directly

- Ship-unloading, directly from vessel cranes and mobile harbour equipment

- Loading vessels and barges, directly from wheel loaders or grab cranes

- Feeding directly into other other equipment

- Feeding fixed equipment

- Reclaiming and discharging onto overland conveyor systems

- Mobile bulk reception hopper, feeding onto Stacker/Re-claimer belt

English

English