Just let we know what you want, and we will get in touch with you as soon as possible!

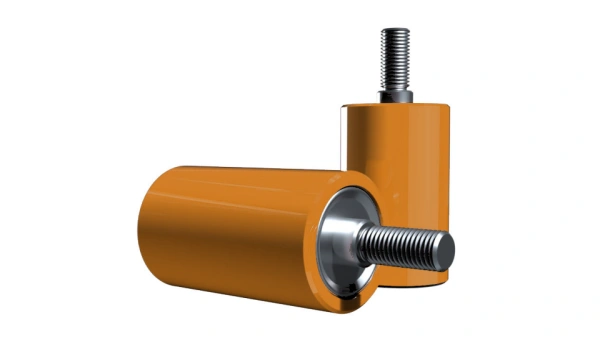

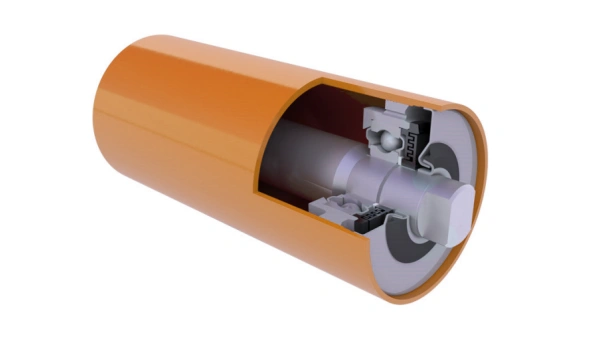

Rubber Ring for Belt Conveyor Roller

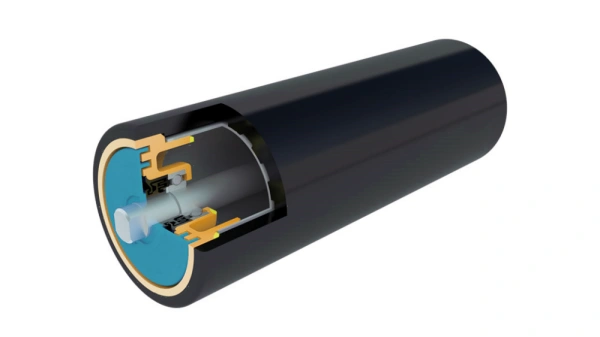

A rubber ring for a conveyor roller — also called a rubber disc, impact ring, or buffer ring — is a protective component fitted around belt conveyor idler rollers. It helps absorb impact, reduce belt wear, minimize noise, and protect the roller shell in heavy-duty or loading-point areas.

Function of Rubber Rings

- Impact absorption: Protects rollers and belts from shock at loading zones.

- Material protection: Prevents damage from falling rocks, ores, or lumps.

- Noise reduction: Damps vibration during belt contact.

- Belt tracking: Improves belt alignment and reduces slipping.

- Wear reduction: Extends roller and belt life.

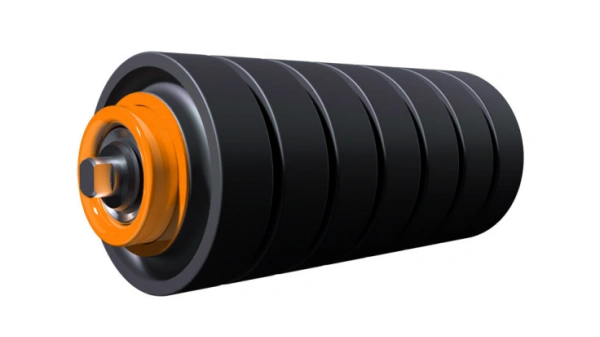

Types of Rubber Rings

| Type | Description | Typical Application |

| Impact rubber ring | Thick and resilient; used on impact rollers for conveyor protection. | Belt loading points |

| Return rubber ring | Smooth or spaced rings; used on rubber disc return roller to clean belt | Return belt section |

| Spiral rubber ring | Rings arranged in spiral; helps remove sticky material | Wet or sticky material lines |

| Buffer ring / Cushion ring | Soft compound; high elasticity | Heavy-load impact areas |

Standard Dimensions

Rubber rings are usually defined by:

- Inner Diameter (ID): Matches roller tube or shaft

- Outer Diameter (OD): Matches idler roller outer size

- Thickness / Width: 10–50 mm depending on model

| Roller Ø (mm) | Typical Rubber Ring OD (mm) | Width (mm) | Inner Ø (mm) |

| 89 | 133–140 | 20–35 | 89 |

| 102 | 152–160 | 25–40 | 102 |

| 108 | 159–165 | 25–40 | 108 |

| 127 | 178–190 | 30–45 | 127 |

| 133 | 194–200 | 35–50 | 133 |

| 152 | 219–225 | 35–50 | 152 |

Material Options of Ring Material

| Material | Features | Typical Use |

| Natural Rubber (NR) | High elasticity, good impact resistance | General purpose |

| Nitrile Rubber (NBR) | Oil and abrasion resistance | Oily materials |

| EPDM | Weather and ozone resistant | Outdoor conveyors |

| Polyurethane (PU) | High wear resistance | Abrasive materials |

Installation of Rubber Ring

- Mounted on steel idler roller shell by press-fitting or vulcanizing.

- Usually spaced 10–20 mm apart for self-cleaning and flexibility.

- Used mainly on impact idlers and return rollers.

Would you like me to provide a dimension chart for impact idler rollers with rubber rings (including number of rings per roller and spacing)? That would help if you're designing or sourcing for a specific belt width (e.g. 800 mm or 1000 mm).

English

English