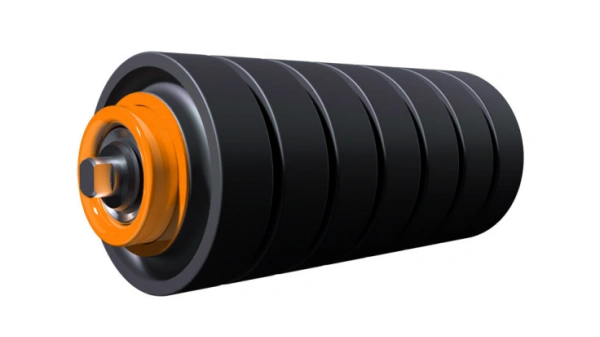

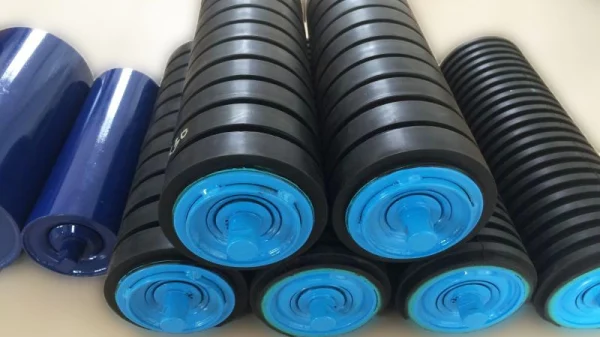

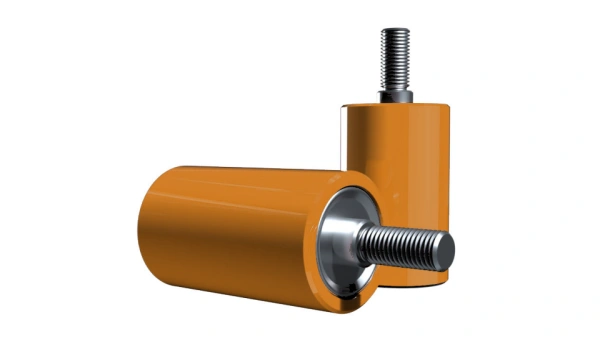

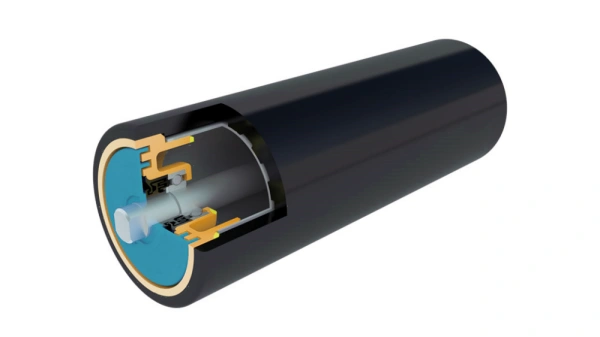

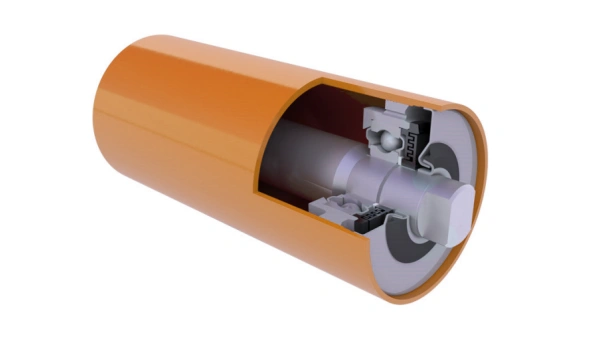

Impact rollers typically have a rubber or polyurethane coating on the roller surface to provide elasticity and absorb impact energy. We can supply impact rollers in a variety of roller diameters, roller lengths and roller shaft diameters.

| Impact Roller Dimension | |

| Standard | DIN, CEMA, JIS, AS, SANS, GOST, AFNOR etc. |

| Shaft Diameter | 15, 20, 25, 30, 40, 45, 50mm |

| Roller Shell Thickness | 3, 4, 6, 9mm |

| Roll Shell Diameter | 60, 63, 89, 108, 133mm |

| Roller Diameter | 89, 108,133, 159, 180, 194, 215mm |

| Roller Length | 160-1600mm |

| Impact Roller Rubber Ring | Normal Rubber Rings or Conical Rubber Rings |

| Bearing Brand | SKF, NSK, FAG, HRB, LYC, ZWZ, C&U |

| Bearing No. | 6202, 6204, 6205, 6305, 6206, 6306, 6308 |

English

English