Just let we know what you want, and we will get in touch with you as soon as possible!

Mobile Bulk Material Handling Experts

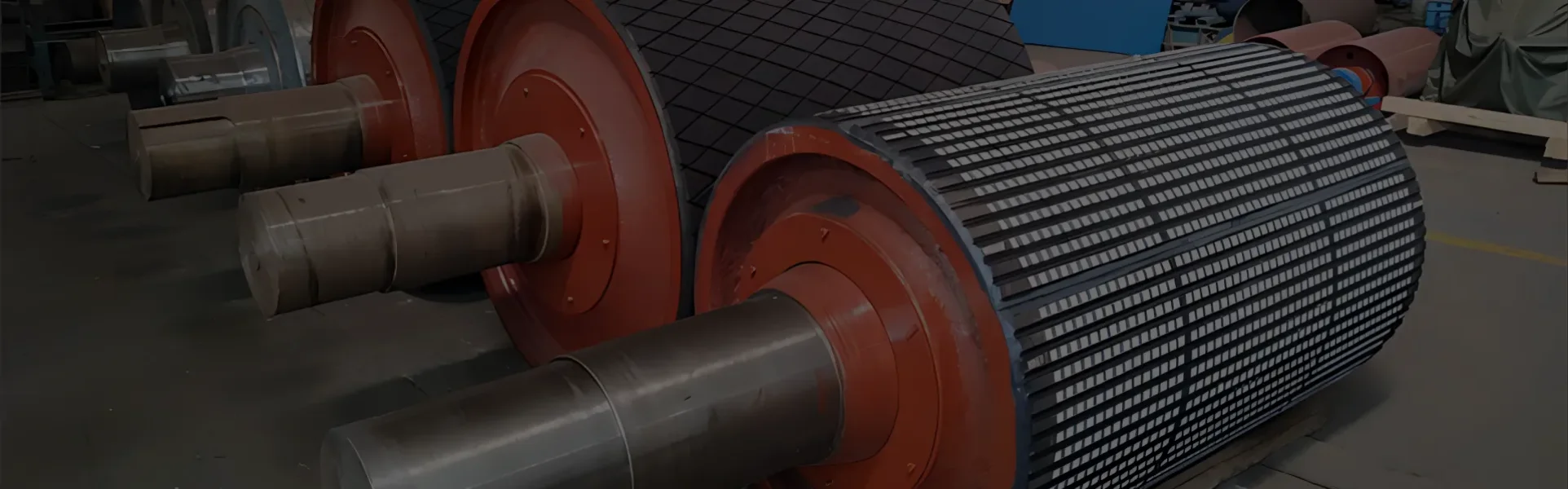

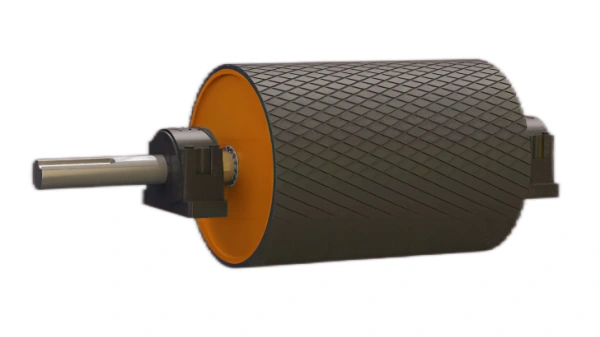

Belt Conveyor Pulley Shaft

The pulley shaft is the central load-bearing and torque-transmitting component of a belt conveyor pulley. It connects the pulley to the bearing housings and drive system, ensuring stable, efficient rotation under varying operating conditions. As a critical mechanical element, the pulley shaft must be engineered with high strength, precise machining, and reliable material properties to withstand continuous bending, torsional, and dynamic loads generated by belt tension and drive torque.

1. Material of Pulley Shaft

Pulley shafts are typically made from high-strength carbon steel or alloy steel with good toughness, fatigue resistance, and machinability. Common materials include:

- C45 / EN8 / AISI 1045: Medium-carbon steel widely used in standard pulleys.

- AISI 4140 / EN19 (Alloy Steel): Higher tensile strength and fatigue resistance; suitable for heavy-duty conveyors.

- AISI 4340 (High-Strength Alloy Steel): Used in extreme-duty or high torque applications (mining, ports).

- Stainless Steel (304 / 316): Used in corrosive, food-grade, or chemical environments.

Heat treatment such as quenching and tempering is often applied to improve yield strength and fatigue life, especially for alloy steels.

2. Pulley Shaft Types

Depending on the pulley design and load requirements, conveyor pulley shafts can be manufactured in several forms:

(a) Straight Shaft

- Uniform diameter along most of its length.

- Used in smaller or lightly loaded pulleys.

(b) Stepped Shaft

- Most common design.

- Features multiple diameters for bearing seats, hubs, and locking elements.

- Distributes stress efficiently and optimizes material usage.

(c) Tapered Shaft Ends

- Used with taper-lock bushings or shrink-disc locking systems.

- Enhances torque transmission.

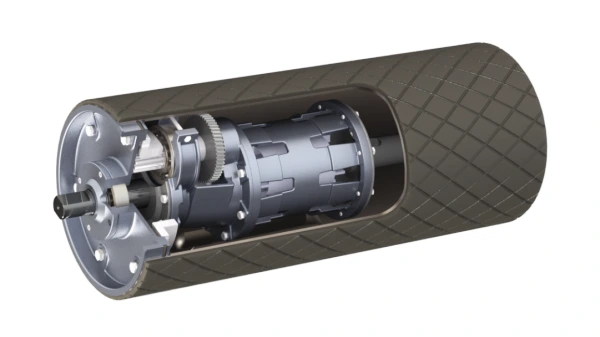

(d) Hollow Shaft

- Reduces weight and bending stress.

- Used in large-diameter pulleys and special applications.

3. Precision & Machining Requirements

Pulley shafts require high machining precision to ensure perfect fit with bearings, locking elements, and end discs. Typical precision requirements:

Tolerance Class

- Bearing seats: h6, h7

- Locking elements: h7/h8

- Keyways: according to DIN 6885

Surface Finish

- Bearing seats: Ra 0.4–0.8 μm

- Seal areas & locking regions: Ra ≤ 1.6 μm

Concentricity & Runout

- Total indicated runout (TIR) ≤ 0.02–0.05 mm depending on size.

Straightness

- Typically ≤ 0.1 mm per meter.

High machining accuracy ensures vibration-free operation, uniform load distribution, and extended bearing and pulley life.

4. Expected Lifespan

The lifespan of a pulley shaft depends on material quality, load conditions, fatigue stress, and maintenance practices.

Typical service life ranges:

- Standard conveyors: 5–15 years

- Heavy-duty mining/port conveyors: 10–25 years

- High-speed or high-tension systems: 3–10 years

- Properly designed & maintained pulleys: Up to 20–30 years

Key factors affecting lifespan:

- Fatigue stress from cyclic bending and torque

- Belt tension level and wrap angle

- Starting/stopping frequency

- Misalignment of bearings

- Corrosion, abrasion, and surface wear

- Material and heat treatment quality

When correctly designed and installed, the pulley shaft often outlasts other components like bearings and lagging.

Need More?

A robust pulley shaft design increases conveyor uptime, reduces maintenance, and ensures safe, efficient material handling. It is therefore essential that the shaft design follows sound mechanical engineering practices, including stress analysis, deflection checks, fatigue evaluation, and compliance with industry standards such as CEMA, ISO, and DIN.

I can also provide:

- Full pulley shaft design procedure

- Stress & deflection calculations

- CAD-style introduction/drawing

- Material comparison table

- Specification sheet for website

Just tell me what you'd like next!

English

English