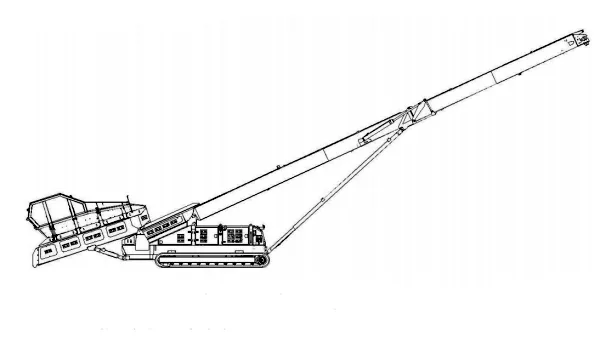

The TLF Series mobile low hopper feeder allows your operator do directly unload bulk materials from grab cranes, wheel loaders and excavators at a low feeding height compared to THF hopper feeder. The lump size is up to 150mm, and the stacking and feeding capacity can reach 1500t/h. The stacking volume can reach 1315 m³ and the stacking height can reach 9.2 meters. The working full length: 14 meters, 18 meters, 20 meters. Here we will talk about the main components of this hopper feeder.

1. Low Hopper Feeder

The low hopper has a lower feeding height than normal hopper feeder. The maximum lump feed size is up to 150mm (6''). It can provide stable materials flowing for incline belt conveyors.

- Adjustable rear lift hydraulics for variable feed height.

- Use impact rollers and impact bars to support belt of belt feeder.

- It is also equipped with rubber skirt to prevent spillage of materials.

- The hopper sides are fold-able for transportation.

Reception Hopper

2. Incline Belt Conveyor

It can be made of foldable plate frame or foldable lattice steel frame, and it features a hydraulic folding head section allowing for compact road transportation. Different steel frame can meet different handle efficiency.

- Plate Steel frame: 500t/h

- Lattice Steel Frame: 1500t/h

Inclined Belt Conveyor for Stockpiling

3. Hydraulic Lifting System

Easy access for maintenance to all hydraulic components such as pumps, filters, tanks, valves etc. Steel fabricated hydraulic tank complete with fill level gauge and lockable filler cap.

- Lifting Hopper for Variable Feed Height

- Lifting Hopper Side Plate for Transportation

- Raising Conveyor for Variable Conveying Height

4. Track Mobile Chassis

Heavy-duty structural steel chassis with integrated web design for rear telescopic mounting. Multiple lockable doors provide easy access to engines, hydraulic systems, fuel tanks, etc.

- Drive: hydraulic motors.

- Tensioning: hydraulic adjuster.

- Frame: heavy duty steel frame.

5. Engine and Control

The controlling system has start up system with safety features.

- Engine monitoring and tracking system

- LED light for equipment checking and maintaining.

- Full frequency certified CE, FCC, AU and Japanese remotes systems.

- Control panel mounted in secure canopy with lockable doors.

- Steel fabricated fuel tank complete with fill level gauge and lockable filler cap.

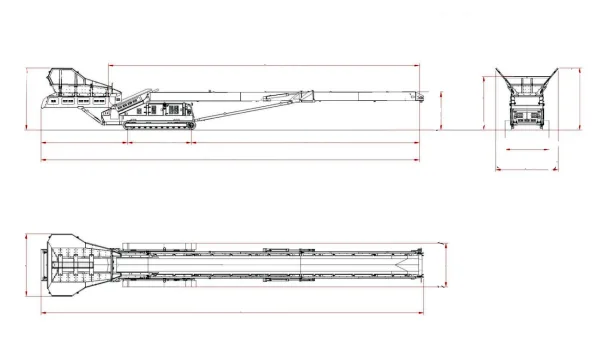

6. Foldable Design Structure

For easy transportation, our low feeder hopper can be folded through hydraulic system.

- Fold Hopper Side Plates.

- Fold Head Section

- Low Incline Conveyor Angle

Low Hopper Feeder Transportation Drawing

The tracked mobile low hopper feeder is a track mounted fully mobile conveyor designed to work at production rates of up to 500tph (plate steel frame for inclined conveyor) or 1500t/h (lattice steel frame for inclined conveyor).

English

English