Just let we know what you want, and we will get in touch with you as soon as possible!

Conveyor Idler Types Explained: Carrying, Return, Impact and Training Idlers

Conveyor idlers are critical components of belt conveyor systems. They support the conveyor belt, maintain proper belt alignment, reduce friction, and help ensure smooth and efficient material transportation. Selecting the correct idler type is essential for extending belt life, reducing maintenance costs, and improving overall system reliability. This article explains the four main conveyor idler types—carrying idlers, return idlers, impact idlers, and training idlers—their functions, designs, and typical applications.

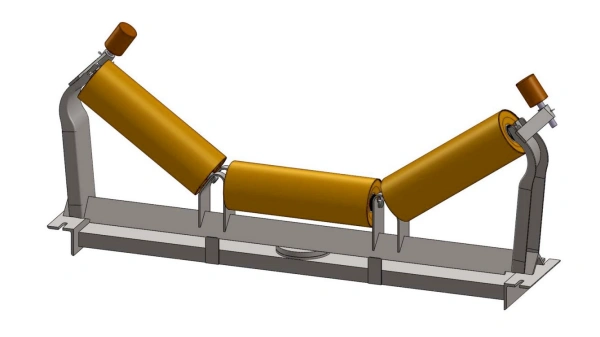

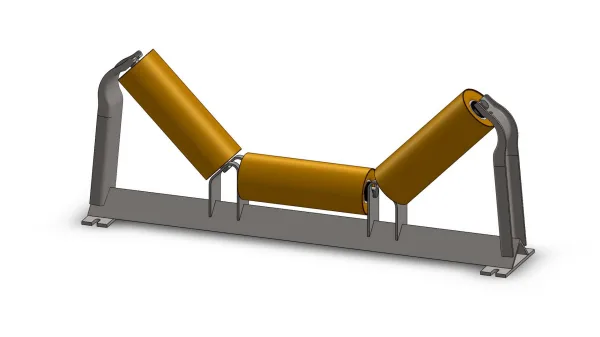

1. Carrying Idlers

Belt carrying idlers support the loaded side of the conveyor belt, bearing the weight of the belt and the conveyed material. They account for the majority of idlers in a conveyor system.

Common Designs

- Troughing idlers (most common):3-roll trough idlers (20°, 30°, 35°, 45° trough angle)

- Flat carrying idlers (for light loads or flat belts)

Key Features

- Designed to distribute material evenly across the belt

- Reduce belt sag and rolling resistance

- Available in steel, HDPE, or rubber-coated rollers

Typical Applications

- Mining conveyors

- Aggregate and quarry plants

- Cement, coal, and fertilizer conveying systems

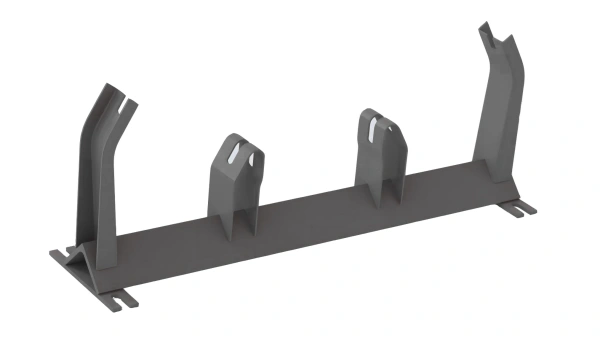

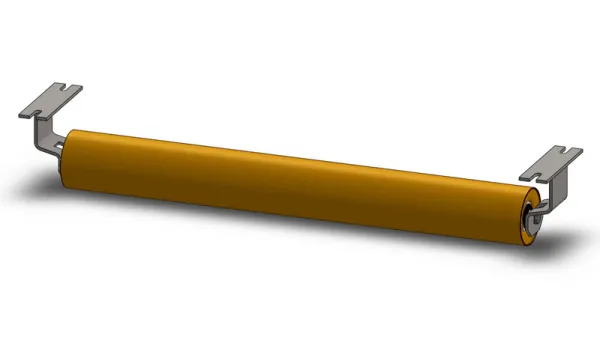

2. Return Idlers

Return idlers support the empty return side of the conveyor belt after material discharge. Their main role is to keep the belt stable and aligned on its return journey.

Common Designs

- Single return idlers

- V-return idlers (used for belt tracking)

- Rubber ring return idlers (for belt cleaning)

Key Features

- Lower load compared to carrying idlers

- Can be fitted with rubber rings or spiral rings to reduce material buildup

- Help minimize belt flutter and vibration

Typical Applications

- Long-distance belt conveyors

- Conveyors handling sticky or wet materials

- Bulk material handling systems requiring belt cleaning

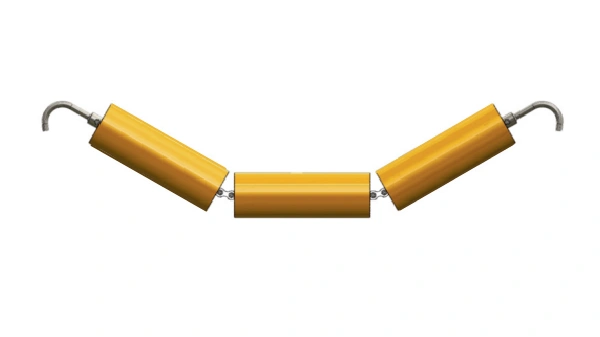

3. Impact Idlers

Impact idlers are installed at loading and transfer points, where material drops onto the belt. Their primary purpose is to absorb impact energy and protect the belt from damage.

Common Designs

- Impact idlers with rubber rings

- Heavy-duty impact trough idlers

- Often installed with impact beds in high-load zones

Key Features

- Rubber rings or cushions mounted on steel rollers

- High shock absorption capability

- Reduce belt wear, splice damage, and roller shell deformation

Typical Applications

- Primary crusher discharge conveyors

- Truck or rail wagon loading zones

- High-capacity mining and quarry conveyors

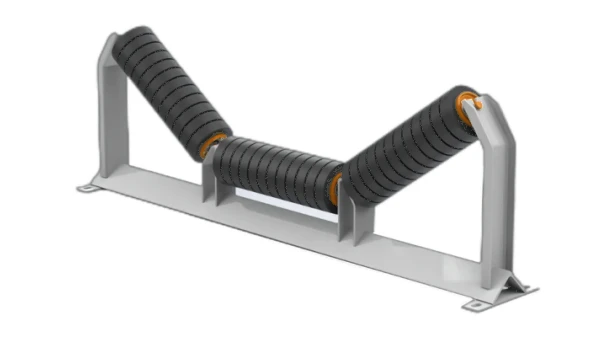

4. Training Idlers (Self-Aligning Idlers)

Training idlers are designed to correct belt misalignment automatically. They pivot or tilt when the belt moves off-center, guiding it back to the correct tracking position.

Common Designs

- Carrying training idlers (for the loaded belt side)

- Return training idlers (for the return side)

Key Features

- Reduce belt edge damage

- Prevent material spillage

- Minimize manual belt tracking adjustments

Typical Applications

- Long belt conveyors

- Conveyors with frequent direction changes

- Systems prone to misalignment due to uneven loading

Comparison of Conveyor Idler Types

| Idler Type | Belt Side | Main Function | Typical Location |

| Carrying Idler | Loaded side | Support belt and material | Entire carrying length |

| Return Idler | Return side | Support empty belt | Return run |

| Impact Idler | Loaded side | Absorb impact | Loading points |

| Training Idler | Both sides | Correct belt tracking | Strategic intervals |

How to Choose the Right Conveyor Idler

When selecting conveyor idlers, consider the following factors:

- Belt width and speed

- Material type and bulk density

- Impact load and drop height

- Environmental conditions (dust, moisture, corrosion)

- Industry standards (CEMA, ISO, DIN)

Correct idler selection improves conveyor efficiency, reduces downtime, and significantly extends belt and roller service life.

Understanding the different types of conveyor idlers—carrying, return, impact, and training idlers—is essential for designing reliable and cost-effective belt conveyor systems. Each idler type plays a specific role in supporting the belt, handling material loads, absorbing impact, or maintaining proper tracking.

Choosing the right combination of idlers ensures smoother operation, lower maintenance costs, and longer conveyor lifespan in mining, quarry, port, and bulk material handling applications.

English

English