Just let we know what you want, and we will get in touch with you as soon as possible!

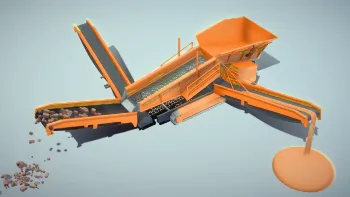

Semi Mobile Hopper for Bulk Material Handling

Semi-mobile hoppers are key equipment in industries such as mining, quarrying, and construction, where they play an essential role in material handling. These hoppers offer the flexibility of mobility, combined with the durability and capacity of stationary equipment. Designed for loading, storage, and transfer of bulk materials like aggregates, ores, coal, and sand, semi-mobile hoppers improve efficiency and reduce costs in operations that require frequent relocation. In this guide, we will explore the features, benefits, and applications of semi-mobile hoppers, showcasing their importance in modern industrial material handling.

semi mobile eco hopper for unloading ship and loading trucks

What is a Semi-Mobile Hopper?

A semi-mobile hopper is a portable bulk material storage and handling device that can be moved between different locations, offering flexibility in material transfer operations. Unlike fully mobile hoppers, which are easily transported between sites, semi-mobile hoppers are designed to be more robust and are usually moved within a confined range using lifting equipment such as cranes or loaders. These hoppers can be fed by trucks, conveyor belts, or excavators, and are used to store and transfer materials to processing plants, conveyors, or other systems.

Key Features of a Semi-Mobile Hopper

1. Robust Construction

Semi-mobile hoppers are built from heavy-duty materials such as steel or reinforced metal to withstand the harsh conditions of industrial operations. Their sturdy construction allows them to handle abrasive materials, large rocks, or fine powders without suffering from wear and tear.

2. High Capacity

Designed to store large volumes of bulk materials, semi-mobile hoppers are capable of holding several tons of material. This capacity makes them ideal for applications where continuous material handling is required, such as in mining or construction sites.

3. Mobility

While not as mobile as fully portable hoppers, semi-mobile hoppers can still be relocated within the worksite using cranes, forklifts, or heavy-duty vehicles. This flexibility is ideal for dynamic job sites where material handling locations frequently change.

4. Feeding Mechanisms

Semi-mobile hoppers are equipped with various feeding mechanisms, such as vibrating feeders, belt feeders, or apron feeders, to ensure consistent material flow into conveyors, crushers, or screens. These mechanisms help regulate the material discharge rate and minimize blockages.

5. Dust and Spillage Control

Many semi-mobile hoppers are equipped with dust suppression systems, such as water sprays or dust covers, to control airborne particles and reduce spillage. This feature ensures a cleaner, safer working environment and minimizes product loss.

6. Adaptability

Semi-mobile hoppers can be configured with different discharge methods depending on the application. They can be designed to discharge materials onto conveyors, directly into processing equipment, or into trucks or containers for transport.

semi mobile hopper

Benefits of Using a Semi-Mobile Hopper

1. Flexibility in Material Handling

One of the main advantages of semi-mobile hoppers is their flexibility. They can be easily repositioned within a worksite, allowing operations to adapt to changes in the material flow, reducing the need for extensive fixed infrastructure.

2. Cost Savings

By using semi-mobile hoppers, companies can reduce transportation costs and optimize their workflow. The ability to store large volumes of material close to the excavation or processing area eliminates the need for continuous trucking of materials, lowering fuel and labor expenses.

3. Increased Efficiency

Semi-mobile hoppers help streamline the material handling process by serving as a buffer between the source and the processing equipment. This ensures a constant supply of material and minimizes downtime due to material shortages or logistical delays.

4. Reduced Environmental Impact

Semi-mobile hoppers reduce the need for large fleets of trucks or vehicles to transport materials, which in turn reduces fuel consumption and carbon emissions. Dust control mechanisms also help minimize airborne particles, improving the environmental conditions of the job site.

5. Safety Enhancements

With their robust construction and dust suppression systems, semi-mobile hoppers contribute to a safer work environment. They reduce the risk of spillage and minimize worker exposure to dust, creating safer conditions for personnel working in heavy industries.

semi mobile hopper for ship unloading

Applications of Semi-Mobile Hoppers

1. Mining

In mining operations, semi-mobile hoppers are used to handle bulk materials such as ore, coal, and overburden. They are positioned near excavation sites to collect and store material before transferring it to conveyors, crushers, or processing plants. Their mobility allows them to be moved as the mining operation progresses, reducing the need for costly and time-consuming infrastructure relocation.

2. Quarrying

Semi-mobile hoppers are commonly used in quarries to store and manage materials such as crushed stone, sand, and gravel. These hoppers help regulate the flow of materials from the extraction site to crushing or screening equipment, ensuring smooth and continuous production.

3. Construction

On construction sites, semi-mobile hoppers are used to handle bulk materials like sand, aggregates, and cement. They are ideal for large infrastructure projects, such as road building or dam construction, where materials need to be transferred efficiently and regularly over short distances.

4. Ports and Terminals

In ports and terminals, semi-mobile hoppers are used to unload bulk materials from ships and transfer them to trucks, conveyors, or storage areas. Their flexibility allows them to adapt to different loading and unloading requirements, improving the efficiency of cargo handling operations.

5. Cement Plants

In cement plants, semi-mobile hoppers are used to store and feed raw materials like limestone, clay, and additives into the production process. They help regulate the material flow into conveyors or grinding mills, ensuring consistent production and reducing material waste.

Key Considerations for Choosing a Semi-Mobile Hopper

1. Material Type

The type of material being handled will influence the design of the semi-mobile hopper. For example, abrasive materials may require reinforced hoppers with liners, while fine powders may need hoppers with dust control features to prevent spillage and emissions.

2. Capacity Requirements

The capacity of the hopper should be chosen based on the volume of material to be handled. For large-scale operations, a higher capacity hopper will reduce the frequency of material transfers and increase operational efficiency.

3. Mobility Needs

Consider the level of mobility required for your operation. If the hopper needs to be moved frequently within the site, ensure that it can be easily transported using existing equipment like cranes or forklifts.

4. Discharge Method

Different materials and processes may require specific discharge methods, such as conveyors, feeders, or direct discharge into trucks. Make sure the hopper's discharge system aligns with your operation's material handling needs.

5. Dust and Spillage Control

For industries that handle fine or hazardous materials, dust control systems are essential to maintain a safe and clean working environment. Consider hoppers with built-in dust suppression features to minimize emissions and ensure compliance with environmental regulations.

6. Durability and Maintenance

Ensure the hopper is built from durable materials that can withstand the harsh conditions of your operation. Look for features that reduce wear and tear, such as liners or impact-resistant components, and consider the ease of maintenance for long-term use.

Semi-mobile hoppers offer a versatile, efficient, and cost-effective solution for material handling in various industries. Their ability to store, transfer, and regulate bulk materials while offering mobility within job sites makes them essential equipment in mining, quarrying, construction, and port operations. By understanding the key features, benefits, and applications of semi-mobile hoppers, you can select the right equipment to optimize your material handling processes, reduce costs, and enhance overall productivity.

English

English