Just let we know what you want, and we will get in touch with you as soon as possible!

Conveyor Cover Clamps for Cover Installing

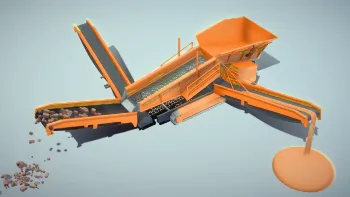

Conveyor cover clamps are essential components used to secure covers on conveyor systems, particularly in aggregate feeding conveyors that transport materials like sand, gravel, and crushed stone. These clamps ensure material protection, enhance safety, and help maintain dust-tight or weather-resistant conditions. Below is a detailed guide to conveyor cover clamps, including their purpose, types, applications, materials, installation, and where to find them.

Purpose and Importance

Conveyor cover clamps play several key roles:

- Fixing: Securely attach the cover to the conveyor structure (channel, angle iron, stringers).

- Sealing: Clamps help create dust-tight seals, minimizing environmental impact in industries such as quarries, concrete plants, and recycling facilities..

- Accessibility: Some clamps offer quick-release or hinged mechanisms for easy inspection and cleaning.

- Stability: Prevent vibration, wind uplift, and material buildup from displacing the covers.

- Safety: By securing covers, clamps restrict access to moving parts, reducing the risk of injury during conveyor operation.

Common Types of Conveyor Cover Clamps

| Clamp Type | Description | Use Case |

| Standard Bolt Clamps | Traditional U-bolt or L-bolt design; requires tools for tightening | Permanent or semi-permanent installations |

| Quick-Release Clamps | Lever or toggle-style clamps that allow tool-free access | Ideal for frequent maintenance or inspections |

| Hinged Locking Clamps | Integrated with hinged covers, allowing the cover to be flipped open | Used in high-maintenance areas |

| Sliding or Hook Clamps | Designed to slide into a frame groove or hook onto a rail | Used in modular or retractable cover systems |

| Stainless Steel or Galvanized Clamps | For corrosion-prone or food-safe environments | Used in outdoor, fertilizer, or chemical plants |

Cover Clamps Material Options

- Galvanized Steel: Coated with zinc for outdoor use, offering up to five times the lifespan of untreated steel in harsh weather conditions. Durable, corrosion-resistant, widely used in mining and aggregates

- Stainless Steel (304/316): Used in corrosive or food-grade environments

- Aluminum or Plastic: Lightweight, but less durable for heavy-duty applications

- Carbon Steel: Cost-effective and durable for standard indoor applications.

How to Choose the Right Clamp

| Selection Factor | Recommendation |

| Cover Material & Thickness | Match clamp strength and shape to the cover type (steel, FRP, plastic) |

| Maintenance Frequency | Use quick-release or hinged clamps if frequent inspection is needed |

| Environment | Use corrosion-resistant clamps in outdoor, coastal, or chemical applications |

| Conveyor Frame Type | Ensure clamp design matches stringer type (C-channel, angle iron, etc.) |

| Belt Width / Cover Radius | Select appropriately sized clamps based on cover profile |

Would you like help selecting a specific clamp model for your conveyor system (e.g., galvanized quick clamps for 1200mm belt width)? I can also suggest standard clamp dimensions or suppliers like SKE Industries who offer complete conveyor cover kits with clamps.

English

English